"TheTurbochargedSquirrel" (thatsquirrel)

"TheTurbochargedSquirrel" (thatsquirrel)

10/29/2018 at 14:25 ē Filed to: None

0

0

24

24

"TheTurbochargedSquirrel" (thatsquirrel)

"TheTurbochargedSquirrel" (thatsquirrel)

10/29/2018 at 14:25 ē Filed to: None |  0 0

|  24 24 |

Photo from the first time I tracked the Mini

In this episode the Squirrel takes his Mini to the track for a 3rd time and promptly FUBARs his brakes for a 3rd time.

I took the Mini with me to work/ instruct at a autocross/track event at Canaan Motor Club (site of last episodeís brake FUBARing). I made some passes at the autocross layout in the morning (a fast layout with speeds reaching 65mph in my 115HP Mini, with one braking zone from that 65mph top speed to about 35 with a further 4 wheel drift down to about 25 (that corner was beyond slippery when it was wet in the morning) and another from about 55 to 20 ), after my 3rd pass you could smell a bit of brakes (to be expected when Hawk HP+ pads are driven hard) and the pedal was a tad squishy, something I put down to the fact that I was driving in my sneakers and not my usual racing shoes.

Fast forward to the afternoon and the students are inside learning about track etiquette while the instructors are making laps to dry the last sector of the track a bit (the autocross layout only used the first half of the lap). Iím doing my laps and with every hard braking zone (In my car Canaan has 1 zone coming from 70 to 35, 1 from 55 to 30 , one from 75 to 60, another from 70 to 30, and a final breaking point from 45 to 30, all over a lap of about 1:45 so not exactly kind to brakes but nothing quite like the 105 to 30 zone at Thompson) the pedal is getting noticeably squishier. I did 4 laps before calling it as the pedal had reached a point where it was soft enough I was starting to get concerned about it getting softer.

Over the course of those 4 laps at no point did the stopping performance lessen in any way. Despite the soft pedal it was still happy to throw out the anchor every time you hit the pedal. The car still stops exactly the way you expect it to, just with more pedal travel. This leads me to believe the car is just boiling the fluid every time you lean on the brakes.

My setup is as follows: Hawk HP+ pads on Centric cryo-treated rotors (vented in front and solid in rear) installed about 5k mi ago in July, factory steel lines in the body with braided stainless steel lines to the factory calipers (installed with the pads and rotors in July), the entire system was flushed and bled with DOT 4 fluid in July, and then flushed and bled again with DOT 4 Synthetic AMSOIL Racing Fluid in September after I got a soft pedal last time I went to Canaan for an autocross . And now after 4 laps at Canaan it needs to be bled again. Itís really beginning to tick me off that I canít get my brakes to not die the instant you use them aggressively over about 60 mph. Itís a 115HP car that only weighs 2,500 LBS, why canít I get it to stop destroying brakes?

After each beating the pads still bite as expected. The pedal just gets soft which leads me to believe the fluid is boiling every time I go to an event. It took 2 20 minute sessions at Thompson on the OEM set-up before the pedal started going soft on me (worth noting that I was actually getting a bit of performance fade on the OEM setup at the end of the first session) and by the end of my 3rd session they were FUBAR. I rebuilt the system with the goal of getting the car to survive a track day but I just made it so that it stops way better but the pedal goes soft in less than 5 minutes. Iím thinking the extra heat produced by the aggressive pads is just too much for the fluid and I donít know what to do about it.

So tell me Oppo, is there anything I can do to get my brakes to survive track use? Is there a fluid beyond DOT 4 racing fluid that I could put in that wonít boil like this?

Iím really starting to think that I should just put a set of OEM pads back on and give up on the idea of ever tracking this car again. It was rather depressing watching the other cars do lap after lap with no issues when I had to park my car after only 4 laps.

Future next gen S2000 owner

> TheTurbochargedSquirrel

Future next gen S2000 owner

> TheTurbochargedSquirrel

10/29/2018 at 14:58 |

|

Brake vents will help keep things cool. Also stainless lines for less flex when hot.

Out, but with a W - has found the answer

> TheTurbochargedSquirrel

Out, but with a W - has found the answer

> TheTurbochargedSquirrel

10/29/2018 at 14:59 |

|

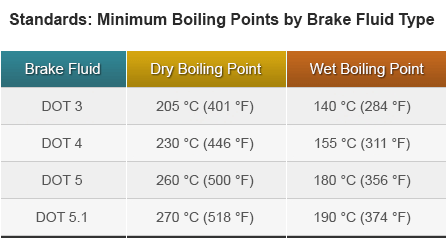

DOT 5.1 should work:

Also, check those wet boiling points. As brake fluid ages and water gets in the system, the heat capacity drops quite strongly.

EDIT: Do check the exact boiling points of your current fluid and what you might get otherwise. The above are minimum ratings, so there are DOT 4 fluids with a higher boiling point than certain 5.1s.

Flynorcal: pilot, offshore sailor, car racer and panty thief

> TheTurbochargedSquirrel

Flynorcal: pilot, offshore sailor, car racer and panty thief

> TheTurbochargedSquirrel

10/29/2018 at 15:00 |

|

I had a similar issue with my Corvette. My problem was that it was an old car and Iíd swap the fluid and after a short while I was stepping on mashed potatoes again. I think it had to do with the piston in the master cylinder traveling more than it had in 20+ years breaking some crusty stuff loose and contaminating the fluid. Along the way I replaced the pads, rotors, lines, etc ó but until I replaced the MC I kept having the same problem. Iím not saying that you need to replace your MC but it sure sounds like you need to consider that your fluid is getting contaminated somehow.

In the meantime adding in some speed bleeders so you can quickly bleed your brakes followed by some aggressive parking lot driving and

another bleed might shake whatever it is loose and one final flush and replace it with SRF brake fluid and hopefully itíll be 90% fixed without replacing anything but fluid.

BeaterGT

> TheTurbochargedSquirrel

BeaterGT

> TheTurbochargedSquirrel

10/29/2018 at 15:10 |

|

Donít know much about tracking Minis but are the stock calipers/brake system cut out for the abuse? What do other Mini people usually do?

Maybe try a different fluid like Motul/Wilwood. Donít know if you can get any additional cooling on them.

TheTurbochargedSquirrel

> Out, but with a W - has found the answer

TheTurbochargedSquirrel

> Out, but with a W - has found the answer

10/29/2018 at 15:18 |

|

Current fluid is rated at 271C. I doubt I need to worry about wet boiling point when the fluid is less than 2 months old.

TheTurbochargedSquirrel

> Future next gen S2000 owner

TheTurbochargedSquirrel

> Future next gen S2000 owner

10/29/2018 at 15:20 |

|

I already have stainless steel lines that I installed after the first time I borked the brakes.

Brake cooling ducts are an idea I have considered but they would have to be a homemade system considering there's no good way to mount or route them on the Mini.

TheTurbochargedSquirrel

> Flynorcal: pilot, offshore sailor, car racer and panty thief

TheTurbochargedSquirrel

> Flynorcal: pilot, offshore sailor, car racer and panty thief

10/29/2018 at 15:26 |

|

Bleeding the brakes on the Mini is a massive pain in the ass process involving a scan tool since BMW decided it would be a good idea to mount the ABS pump at the highest point in the system so thatís where all the air ends up.

I would have to see what the fluid looks like when I bleed it but the fluid in the resovoir hasn't picked anything up. I'm thinking I will bleed them again in a few weeks when I swap over to snows (another debacle to deal with since I didn't rotate the tires between the last few autocrosses of the season and the bolts bind up like crazy when you beat on it, I tried swapping them the other day and they just didn't want to come off).

Out, but with a W - has found the answer

> TheTurbochargedSquirrel

Out, but with a W - has found the answer

> TheTurbochargedSquirrel

10/29/2018 at 15:27 |

|

Hmm. You could try something extreme like Motul RBF660 (328įC dry)...

Alternatively, may I suggest turbofan wheels for increased brake cooling?

TheTurbochargedSquirrel

> BeaterGT

TheTurbochargedSquirrel

> BeaterGT

10/29/2018 at 15:28 |

|

The Minis are known for being hard on brakes but most issues are just excessive wear, not soft pedals. Most people recommend just moving to a higher performance pad and fluid combo for track use.†

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

10/29/2018 at 16:15 |

|

So, hereís a true story. Know the Mini JCW Factory team running in IMSA ST? Yep. I got a ridealong with the owner in his JCW at Mid-Ohio. And we talked brakes.

Because a perfectly maintained, techíd, manual JCW with track pads had completely and utterly cooked the brakes within three laps . With several minutes of cooldown between them. This is a car that IMSA has OKíd to take ordinary folks around the track at speed . (And believe me, Luis was going for it, and his lines were dead-on. Mid-Ohio is my home track, ya know.) By the third go-round - which was mine - he was having pedal issues right after Madness. It was that bad . And thatís a JCW with the big brakes.

Fact is, the Mini does not have jack shit for brake cooling. It has brake heating. Thatís what it is. Itís a problem Iím all too familiar with.

What I would recommend, quite honestly, is just calling LAP . (Luis is the guy with the gray hair. Great guy.) They know these cars far better than I do. And the ST rules do not permit them to use non-factory system components OR larger brakes (5% of diameter) , so they know where to put your money to make what you have work.

RallyWrench

> TheTurbochargedSquirrel

RallyWrench

> TheTurbochargedSquirrel

10/29/2018 at 16:41 |

|

Duct them. The fronts, at least. Airflow makes a ton of difference even on stock brakes , I think the JCWs have big ducts that you might be able to work into it somehow , or just use some 3" flexible dryer tubing or something like that. Not a lot of room in the front of these things, but if you get air to the inside of the brakes itíll make a world of difference.

ItalianJobR53 - now with added 'MERICA and unreliability

> TheTurbochargedSquirrel

ItalianJobR53 - now with added 'MERICA and unreliability

> TheTurbochargedSquirrel

10/29/2018 at 17:03 |

|

You could use these: https://www.waymotorworks.com/mini-brake-ducts.html

Or create similar ones using some flexible tubing.

Do you have fog lamps or fog lamp covering trim in the bumper? It should be a straight shot to the calipers if you cut the inner plastic fenders. Routing to the hub itself can be tough from what Iíve read about it .

TheTurbochargedSquirrel

> ItalianJobR53 - now with added 'MERICA and unreliability

TheTurbochargedSquirrel

> ItalianJobR53 - now with added 'MERICA and unreliability

10/29/2018 at 17:20 |

|

I have considered those but they are pricey and wonít fit the standard R50 bumper. My current plan would be to remove the plastic vent things that block where the fogs would be and then cut that section of the radiator support (though I should probably just replace the rad support while I have the bumper off since itís cracked) and then try to figure out how to run tubing without kinking it.

TheTurbochargedSquirrel

> RallyWrench

TheTurbochargedSquirrel

> RallyWrench

10/29/2018 at 17:23 |

|

The 2005+ JCWs did have ducting available but I canít retro fit them onto my car due to differences in the structure in the front of the car. Honestly the best plan for ducting on mine would be to take a sawzall to the rad support and fender liners and run a hose from the fog light holes in the bumper and then zip-tie that to the suspension pointed vaguely at the caliper.

TheTurbochargedSquirrel

> Spamfeller Loves Nazi Clicks

TheTurbochargedSquirrel

> Spamfeller Loves Nazi Clicks

10/29/2018 at 17:33 |

|

Wait, he cooked the brakes on an IMSA ST Mini? I donít believe that, the JCW STs are known for their braking performance. Itís what makes them so good at tracks like Watkins Glen. Watkins Glen just fucks brakes with all of itís big downhill braking zones and the Miniís have stamped their authority on that event the last 2 years.

I agree that Mini does basically nothing from the factory for brake cooling. It also doesnít help that basically doesnít use the rear brakes either.

TheTurbochargedSquirrel

> Out, but with a W - has found the answer

TheTurbochargedSquirrel

> Out, but with a W - has found the answer

10/29/2018 at 17:40 |

|

Iím really tempted to find the DOT 4 fluid with the highest boiling point and just run that.

I donít even want to know how much of a pain in the ass it would be to clean HP+ brake dust out of a turbofan.

Out, but with a W - has found the answer

> TheTurbochargedSquirrel

Out, but with a W - has found the answer

> TheTurbochargedSquirrel

10/29/2018 at 17:43 |

|

A very big one. I guess itís why they come with covers.

ItalianJobR53 - now with added 'MERICA and unreliability

> TheTurbochargedSquirrel

ItalianJobR53 - now with added 'MERICA and unreliability

> TheTurbochargedSquirrel

10/29/2018 at 17:53 |

|

Damn, didnít know that the bumpers were different for R50 and 53.

Radiato r support is expensive for the 53 ($300) hence why I wont change mine.

You can try something like this perhaps:† https://www.specr53.com/blog/diy/mini-brake-duct-diy/

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

10/29/2018 at 18:12 |

|

No, the Hot Lap car is a completely stock Mini JCW (2 door coupe) fully optioned. (Itís actually his daily driver.) Only changes were brake pads and tires. You canít take a passenger in a one seat car, man. Well, I mean you kinda can, but IMSAís insurance isnít gonna cover it.†

Thatís why Iím saying, call them. As I mentioned, ST rules do not allow changing the brake system aside from bias and the option to delete ABS . (Mid-Ohio, BTW, is MUCH nastier on brake cycling than Watkins.) And remember, theyíre also NOT allowed to have any ducting unless using the stock fog lamp openings.

If anybody has a recipe that works with the stock brakes, itís LAP, period.

TheTurbochargedSquirrel

> Spamfeller Loves Nazi Clicks

TheTurbochargedSquirrel

> Spamfeller Loves Nazi Clicks

10/29/2018 at 20:05 |

|

Plenty of manufacturers do events where they slap a passenger seat into their race car. As for the track differences you hear a lot more concern and see a lot more brake issues at Watkins than you do at Mid Ohio. At the end of the day my R50 is a very different car to the modern F56. Sliding single piston caliper vs fixed 4 piston, larger rotors on the JCW than mine, and LAP probably builds off the existing air ducting into the wheel well on the JCW while I have a decent amount of cutting that would have to be done to get any ducting from the bumper to the wheel. I should probably try to figure out what was run on the first generation Mini challenge cars as they were R50 based.

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

10/29/2018 at 21:37 |

|

Itís an issue of HOW youíre braking. Mid-Ohio is a lot of on-off, so the cycling is worse. Watkins is less severe on cycling, more severe on wear. Cycling is what cooks worst - the hard on and off. Something that isnít an issue with a full race setup because of significantly higher boiling points. Since they donít have fluid problems and much better thermal control , itís a question of wear. For a street car, itís an issue of boiling points and heat in the system.

Your braking points - by your own account - are significantly less severe than Mid-Ohio as well. Back straight into China Beach is 130MPH+ down to 50MPH up as fast as you can down below 40 immediately into a long downhill trail straight into WOT. And youíre doing that initial absolutely full force because you NEED to be on the throttle going up into the Madness braking zone. There is a lot of high triple-digits to sub-60MPH.

And again, thatís exactly why Iím telling you LAP. They have extensive experience with racing Minis

period

and are the official Factory Team. Which means they have the knowledge and resources for your car as well. They are the people who know what to do to a Mini, no qualifiers.

And if Mid-Ohio can cook a JCW that fast? Yeah. Plus b

rakes are that one item

where you do not call anyone

but

an experienced professional under any circumstances.

I mean seriously, you think I do all the brake design work on my own stuff? Fuck. No. I am not an expert in friction materials, hydraulic pressure management, or the math involved in figuring out how much it takes to stop X in Y distance. And I canít afford to throw parts on, test, throw different parts on, test again. All I do is the mechanical, circuit layout, and ABS. (Of course, thereís a lot of back and forth on the details. But I defer to them by and large.)

And yes, Iím quite certain you need the real professionals. The R50's caliper setup is not substantially different from what I am most knowledgeable on - large bore single piston and 2500-2750lbs with ~90/10. Youíve just got entirely too much temp going into the hydraulic and sounds like none coming out. Thatís going to be a caliper and bias issue, possibly involving ABS as well since soak may be poor fluid cycling. (Which believe me, is a lot less miserable than good conduction but nonexistent rotor cooling.)

Other folks that might be worth a call, depending how serious you are (or arenít) about competition would be Wilwood. Theyíve done a fair bit of development for Minis as well and do nothing but brakes. Wilwood is probably who I would recommend if youíre just looking to make the sponge go away with a brake upgrade ; LAP is who I would call to answer what parts and setup for the whole chassis to maximize within the class rules .

TheTurbochargedSquirrel

> Spamfeller Loves Nazi Clicks

TheTurbochargedSquirrel

> Spamfeller Loves Nazi Clicks

10/29/2018 at 22:11 |

|

Canaanís a little 1.3 mi, 9 turn club track and is no where near as hard on equipment as the bigger pro tracks. Itís only not kind to brakes because of the stabby way the course makes you use the brake and lack of any real resting time for the brakes . A properly fast car barely hits 110 at Canaan. Itís got nothing on the big tracks which is why I need to figure out these brakes. I really want to take this car to the likes of Watkins, Lime Rock, VIR, etc but right now my brakes would be gone by the end of my out lap (it would probably survive at Lime Rock but thatí s only because with 115HP in a little FWD I would only be leaning on the brakes once per lap at Lime Rock).

Right now my plan is to take a sawzall to the fog light mounting structure so I can run some kind of duct from the holes in the bumper to put air onto the caliper/rotor. Itís a daily driver/autocrosser/track toy so I donít have to worry about fitting any specific class, I just want to get it to not die whenever it sees a course with speeds over 60 mph.

I wouldnít go Wilwood because thereís no point in spending $2k+ on brakes I canít even fit my winter wheels over and I havenít actually heard anything good about their kit for the Minis. The people I know who do run them complain about the durability, pedal feel, and consistency of the system.

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

Spamfeller Loves Nazi Clicks

> TheTurbochargedSquirrel

10/29/2018 at 23:35 |

|

ďItís only not kind to brakes because of the stabby way the course makes you use the brake and lack of any real resting time for the brakes. A properly fast car barely hits 110 at Canaan.Ē

Yeah, so a similar profile to Mid-Ohio in that you donít get cooling time. You think you do, but no. You really donít get a lot of cooling time because of how tight packs run.

Having run Lime Rock, youíd actually be fine if itís load

time because in your car, youíll be doing more trail braking and you canít carry into the corners anywhere

near

as hard as I did. But the bias may be screwing you there. I honestly donít have the knowledge to say for sure, but I am comfortable saying it should go better than a 1.3 short

as long as you do not overcook it into turn one!!

Seriously - brake early instead of

hard, and try to drag instead of brake as much as you possibly can so youíve got more pedal into the esses. Youíll also be able to leverage engine drag to reduce your braking going into Uphill and should be able to go no-brakes through Diving.

ďRight now my plan is to take a sawzall to the fog light mounting structure so I can run some kind of duct from the holes in the bumper to put air onto the caliper/rotor.Ē

Steward check it first!!

Last I was active,

I was told that if I put in ANY additional aero including ducts, that unequivocally screwed me harder on class than I was already getting screwed. Stance in my experience

has been that brake ducts are NOT safety, whereas pads/rotors/calipers are.

ď Itís a daily driver/autocrosser/track toy so I donít have to worry about fitting any specific class, I just want to get it to not die whenever it sees a course with speeds over 60 mph.Ē

And this is exactly why you want to steward check it and watch the regulations very closely. If you donít, you will get punted in a fashion worse than I did. I got punted up multiple classes because of lap times, and fell into a performance gap. If you get punted into a class youíre uncompetitive in just by mods, takes the fun out of things immediately. If they give you a waiver, get it in writing from region .

ďI wouldnít go Wilwood because thereís no point in spending $2k+ on brakes I canít even fit my winter wheels over and I havenít actually heard anything good about their kit for the Minis. The people I know who do run them complain about the durability, pedal feel, and consistency of the system.Ē

Honest answer there is that I would blame the installers and part selection and not Wilwood. Itís easy to fuck up brakes when itís an off the shelf BBK, and most people do . Plus BBKs are Ďone size fits mostí and people never read the instructions. They think itís just ďbolt it up and go.Ē Yeah well you just changed all of the capacities and pressures so, no, itís most definitely not. Which is also why I would recommend calling Wilwood rather than just buying their BBK. Any idiot can throw 6 pistons at a problem and pretend they donít need to examine the master cylinder or ABS. And for MOST people who buy them? Itís looks, not real performance.

For you? Yeah. No. Wilwood has a 4 piston split caliper front kit in 12.19 and 11.75 (clears down to 15") that uses a 78xx pad and GT36 rotors. The whole package is $1100. Kit 140-8740 . Again, theyíd be the only ones who can tell you if thatís the right kit for you. But my guess would be yes. And they should be able to advise on compounds and adjustments.

ITA97, now with more Jag @ opposite-lock.com

> TheTurbochargedSquirrel

ITA97, now with more Jag @ opposite-lock.com

> TheTurbochargedSquirrel

10/30/2018 at 10:25 |

|

Welcome to FWD racecars. If youíre driving at anything close to the limit for more than a couple of laps youíre going to have to duct the front brakes on a FWD car. Youíre also going to eventually progress to running harder than what HP+ pads will do, but that it is for another day. A NACA duct is great, but any hole you can find like the fog light mounting location will be better than none. Run your tubing to and down the lower control arms via zip tie (cutting or massaging a radiator support can be an option, but if you plan to actually race the car later on study the class rules, as modifying a radiator support or other bodywork behind bumper cover isnít always allowed, even for brake ducts). Remove the backing plates from the front rotors and throw them in the trash and point the duct outlet where it gets a clean shot at the back of the rotor. If you want to get fancy you can incorporate the duct into the backing plate, but itís not necessary at this level.

Donít point the duct at the caliper, nobody does that on production based race cars. Point it at the rotor. The rotor has two jobs: a friction surface and being the largest heat sink in the braking system. Heat from the caliper is supposed to be conducted to the rotors via the pads. Get some fresh air cooling the heat sink and youíll cool the rest of the system.

https://www.pegasusautoracing.com/advcat.asp?CategoryID=BRAKEDUCT

I can get you some pictures of what I run on the racecar if you want.

As a matter of prep, you generally bleed the brakes before and after every track day on a street driven FWD car.